Outline Srl | All Rights Reserved – Tutti i diritti sono riservati | Sede Legale: Via Giuseppe Marcora 11 - 20121 MILANO (MI) | Tel. +39 3518342152 | Email Info@outlineperforation.com | P. IVA IT 14451460969

SERIE CP/M

The CP/M series includes all our cold micro-drilling, embossing, and multi-cutting machines.

Our team of engineers has optimized this series of units for multiple processes, offering our customers a versatile machine: thanks to the quick change of the main shaft, optimized to be easy and quick to replace, the machine can be adapted to different processes with minimal effort.

MODEL

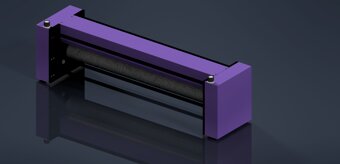

CP80/CPM 80

Our CP80 model is the basic version of our cold micro-perforation units: economical, compact, and easily integrated into most production lines.

Thanks to its small size and lack of complex electronics, it is ideal for production that does not require holes with an aesthetic function. Operating speeds can vary considerably depending on the material and the counter-roller used.

The CPM80 model differs from the “non-M” version in that it has an additional motor, which allows the speed of the needle roller to be matched to that of the production line. The decision to include or exclude the motor depends on several factors: we recommend contacting the Outline team for advice on the version best suited to your needs.

TECHNICAL SPECIFICATIONS

Maximum speed: variable

Air (recommended pressure): 5 to 6 Bar

Shaft diameter: 79 mm

Counter roller: natural fiber tampico or rubber from 60 to 95 shore

Maximum width: 1800 mm

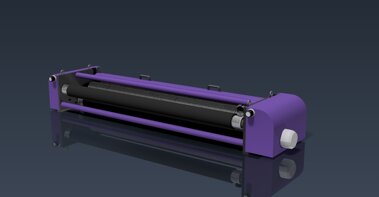

CP100/CPM100

Our CP100 model is the intermediate unit in the micro-perforation series. It is equipped with a 99 mm shaft, capable of sustaining higher speeds and with a much higher needle density than the previous model.

It is available in vertical and horizontal versions.

Although all models in the CP/CPM series can perform micro-perforation, multi-cutting, and embossing, based on our experience, the CP/CPM100 is the most suitable for most applications. The CPM100 model differs from the “non-M” version in that it has an additional motor, which allows the speed of the needle roller to be matched to that of the production line. The decision to include or exclude the motor depends on several factors: we recommend contacting the Outline team for advice on the version best suited to your needs.

TECHNICAL SPECIFICATIONS

Maximum speed: variable

Air (recommended pressure): 5 to 6 Bar

Shaft diameter: 99 mm

Counter roller: natural fiber tampico or rubber from 60 to 95 shore

Maximum band: 2200 mm

CP150/CPM150

Our CP150 model is the top of the range in this series. Equipped with a 149 mm shaft, it is capable of reaching very high speeds: in the motorized version, it can reach up to 350 m/min in optimal conditions.

Available only in the horizontal version, it is the perfect unit when high performance is required or when a very wide perforation range is needed: with this model, a perforation range of up to 3000 mm can be achieved.

The CPM150 model differs from the “non-M” version in that it has an additional motor, which allows the speed of the needle roller to be matched to that of the production line. The decision to include or exclude the motor depends on several factors: we recommend contacting the Outline team for advice on the version best suited to your needs.

TECHNICAL SPECIFICATIONS

Maximum speed: variable

Air (recommended pressure): 5 to 6 Bar

Shaft diameter: 149 mm

Counter roller: natural fiber tampico or rubber from 60 to 95 shore

Maximum belt width: 3000 mm