Outline Srl | All Rights Reserved – Tutti i diritti sono riservati | Sede Legale: Via Giuseppe Marcora 11 - 20121 MILANO (MI) | Tel. +39 3518342152 | Email Info@outlineperforation.com | P. IVA IT 14451460969

UNITS

We have a wide catalog of units designed to meet every need for micro and macro perforation of moving film.

Our offer ranges from semi-machines to be integrated into existing production lines to complete, compact, and integrated unwinding and rewinding systems, ensuring flexible solutions suitable for different production configurations.

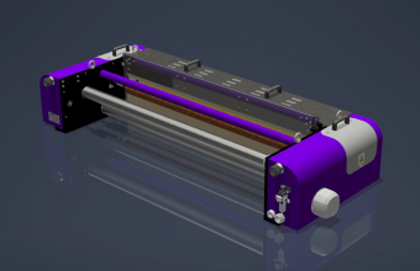

HP Series

The HP series includes the entire range of our hot micro perforators, designed to ensure high performance according to different production needs.

Based on the operating dimensions and working speeds, the series is divided into three models: HP100, HP150, and HP200.

The models mainly differ in three fundamental characteristics:

speed,

shaft diameter,

heating power.

Technical features by model:

HP100

Speed: up to 100 m/min

Shaft diameter: 99 mm

Heating power: 0.5 kW per 100 mm²

HP150

Speed: up to 170 m/min

Shaft diameter: 149 mm

Heating power: 1.0 kW per 100 mm²

HP200

Speed: up to 230 m/min

Shaft diameter: 199 mm

Heating power: 1.5 kW per 100 mm²

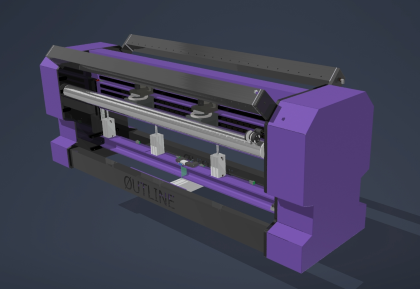

OMP SERIES

The OMP series includes the entire range of our macro punchers, designed for industrial applications that require robustness, precision, and operational flexibility.

The models available in the series are: OMP, OMP2, OMPA2, HOMP2, and HOMPA2.

Main features by model:

OMP

Basic model with punch bodies mounted on one side only.

Maximum punch speed: 45 Hz

Punch diameter: from 1 to 30 mm

Maximum working width: 1800 mm

OMP2

Differs from the OMP model by mounting punchers on both sides and a higher operating speed.

Maximum speed: up to 90 Hz (with punchers aligned on the same line)

Punch diameter: from 1 to 30 mm

Maximum working width: 1800 mm

OMPA2

Version with enlarged bridge, designed to facilitate maintenance operations.

Possibility of lowering the lower bridge for easier matrix maintenance.

Punchers mounted on both sides.

Maximum speed: up to 90 Hz (with punchers in line)

Punch diameter: from 1 to 30 mm

Maximum working width: 2500 mm

HOMP2 / HOMPA2

Models with bridges designed for large punching diameters.

Punch diameter: up to 150 mm

Possibility of lowering the lower bridge

Punchers mounted on both sides

Maximum speed: up to 15 Hz

Maximum working width: 3500 mm

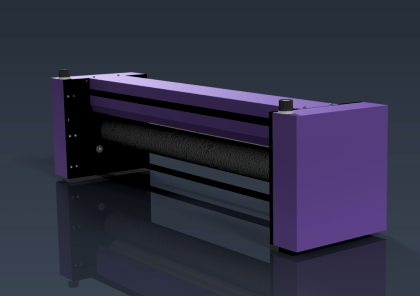

CP/M Series

The CP/M series includes the entire range of our cold micro punchers, embossers, and multi-cutting systems, designed to offer maximum application flexibility.

This series has been developed and optimized by our engineering team to allow multiple processes with the same unit. Thanks to the simple main shaft change, specifically designed to be quick and easy, it is possible to efficiently reconfigure the machine, reducing downtime and operating costs.

Available models

The three main models of the series are:

CP80

CP100 / CPM100

CP150 / CPM150

The differences between the models mainly concern the shaft diameter, available in the following sizes:

79 mm

99 mm

149 mm

Motorized versions

The versions identified by the code “M” are motorized.

Even the non-motorized versions are still prepared for future motorization, through:

an easy-to-install plug & play kit, or the intervention of one of our specialized technicians, who can carry out the installation in just one day.

Counter roller

The counter roller is available in different configurations, depending on the type of process and the desired hole:

Tampico in natural or synthetic fiber

Rubber with different degrees of hardness

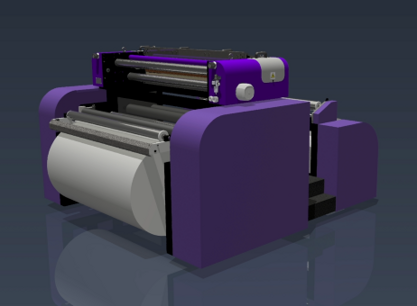

UR SERIES

The UR and URC series include the entire range of our rewinders and mini slitters, compact and economical solutions developed to ensure maximum integration and optimization with all our processing units.

Available models

The following models are part of the UR and URC series:

UR100 / URC100

UR150 / URC150

UR200 / URC200

Main features

The main differences between the models concern the operating speed, which varies:

from 150 m/min for the most compact model,

up to 250 m/min for the model with the highest capacity.

The URC versions are equipped with the function for cutting the mother roll into smaller rolls.

Configurations and capacity

On request, it is possible to configure multiple modules to obtain a single integrated solution that includes two or more of our units.

Management of rolls with a diameter between 600 mm and 1000 mm.

Maximum working width: 2000 mm.

To identify the model best suited to your production needs, we invite you to contact the Outline team, who will be happy to provide you with dedicated advice.

.png)