Outline Srl | All Rights Reserved – Tutti i diritti sono riservati | Sede Legale: Via Giuseppe Marcora 11 - 20121 MILANO (MI) | Tel. +39 3518342152 | Email Info@outlineperforation.com | P. IVA IT 14451460969

SERIE UR/C

The UR and URC series comprise our entire range of rewinders and mini slitters, compact and economical solutions developed to ensure maximum integration and optimization with all our processing units.

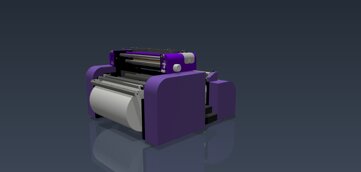

MODEL

UR100/URC100

Our UR100/URC100 model is the most basic model in the series, designed with simple but high-quality components.

It fits perfectly with all our basic lines, with a maximum speed of 150 m/min, deliberately limited to ensure full compatibility with basic units. Compact and economical, like every entry-level model in our range, it is designed for customers who want to start small production runs or for those who are new to the micro and macro perforation sector and have a limited budget to start with.

The system handles reels up to 600 mm in diameter; the “C” version is equipped with film cutting knives, allowing it to be converted into several smaller reels.

The system is managed by Siemens components and an HMI panel, developed in collaboration with industry operators to create optimized, intuitive, and easy-to-use software, suitable even for novice operators.

TECHNICAL SPECIFICATIONS

UR100/URC100

Speed: 150 m/min

Maximum master reel diameter: 600 mm

Maximum web width: 1800 mm

Air pressure: 6.5 BAR

Control: PLC and HMI

Load cells: yes

Edge guide: yes

Film break sensor: yes

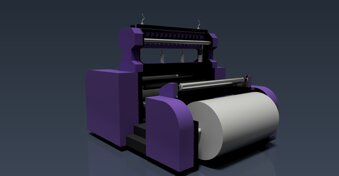

UR150/URC150

The UR150 / URC150 model represents the intermediate solution in the series and is designed for manufacturers who do not accept compromises and boast solid experience in plastics processing.

The machine is made with top-quality components, selected from the best brands in the industry, and with a structure designed and built in-house using cutting-edge design software. This ensures extremely precise film tension control, made possible also by the use of load cells. The line reaches speeds of up to 250 m/min and handles reels with diameters of up to 800 mm.

The “C” version (URC150) is equipped with knives for cutting the film, allowing it to be converted into several smaller reels.

Compared to the smaller model, the UR150/URC150 stands out for its higher line speed and upgraded hardware, with larger diameter rollers.

TECHNICAL SPECIFICATIONS

UR150/URC150

Speed: 250 m/min

Maximum parent reel diameter: 800 mm

Maximum web width: 2000 mm

Air pressure: 6.5 BAR

Management: PLC and HMI

Load cells: yes

Edge guide: yes

Film break sensor: yes

Reel core: 76 mm

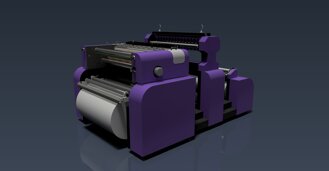

UR200/URC200

The UR200 / URC200 model is the top of the range in the series, designed to offer maximum performance in micro and macro drilling.

It reaches a line speed of up to 350 m/min and handles reels with a diameter of up to 1,000 mm, with cores from 76 to 154 mm.

The machine is equipped with load cells, inverters, and brushless motors, ensuring extremely precise tension control, even when processing the most difficult materials.

In the URC version, the machine is equipped with blades for cutting the film for conversion into smaller reels and, in addition to the other models in the series, a suction system for trimming.

Designed for highly specialized customers, the UR200/URC200 is a complete, no-compromise system, ideal for intensive production. As with all models in the series, additional Outline modules can be integrated, providing a versatile solution suitable for all plastic film processing applications.

TECHNICAL SPECIFICATIONS

UR200/URC200

Speed: 350 m/min

Maximum parent reel diameter: 1000 mm

Maximum web width: 2000 mm

Air pressure: 6.5 BAR

Management: PLC and HMI

Load cells: yes

Edge guide: yes

Film break sensor: yes

Trimming management: yes

Reel cores: from 76 mm to 154 mm